Band Saw

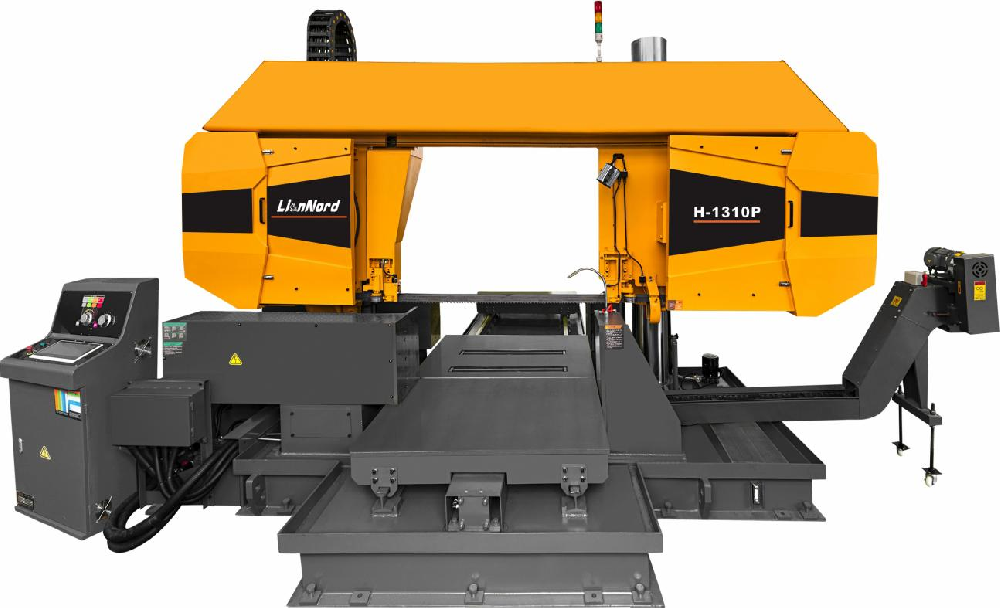

Cnc automatic Intelligent angle rotary Stainless steel bar and pipe Metal cutting band saw machine

Max cutting size 1300x1000mm (WxH)

The machine is suitable for cutting hard materials such as titanium alloys, high-temperature alloys, and aviation materials with specialized sawing machines

The cutting efficiency is twice that of ordinary machines

Make cutting hard materials easier

Benefits at a glance

Max cutting size 1300x1000mm (WxH)

The machine is suitable for cutting hard materials such as titanium alloys, high-temperature alloys, and aviation materials with specialized sawing machines

The cutting efficiency is twice that of ordinary machines

Make cutting hard materials easier

H-1310 Metal Band Machine | |

Cut Size | W*H 1300*1000mm |

Round: 1000mm | |

Blade size | 10000X67X1.6mm |

Blade Speed | 15-80 m/min |

Blade Feeding Speed | 0-300 mm/min |

Maximum load productivity test | Carbon steel≥90 cm2/min |

Perpendicularity of the end face of the saw workpiece | Vertical 0.15/100mm |

Machine Motor | 18kw |

Hydraulic Motor | 3.75kw |

Coolant Motor | 180w |

Machine size | 5800x4700x3000(L×W×H) |

Weight | >13T |

Language | Chinese/English/Russia |

H series horizontal metal band sawing machine is a new type of electromechanical equipment developed by the company with German technology. The product is the essence of similar products at home and abroad, with high technology content, high sawing accuracy and efficiency, and has a long service life, simple operation and convenient maintenance. It is an ideal equipment for sawing small and medium batch materials. The double column gantry band sawing machine is an efficient band sawing machine with beautiful appearance design, structural design, good stability, and strong rigidity. Specially designed for heavy-duty, large and medium-sized general machinery, molds, forging, metallurgy, mining machinery, ships, bridges, metal materials, square materials, round materials, etc. It can also adapt to sawing and processing various black and non-ferrous metal materials.

The main structure and process description of this machine tool are as follows:

1. Bed bucket section

The bed bucket is a box shaped welded structure with sufficient rigidity. It is equipped with feeding devices, clamping devices, column bases, cooling water tanks, etc.

2. Column section

Single hydraulic cylinder design, combined with large diameter columns and ultra long sliding sleeves (with self-lubricating bearings), forms a stable sawing structure. The surface is coated with hard chrome for tight grinding, which is very wear-resistant. The guide sleeve is made of self-lubricating wear-resistant material, and there will be no crawling phenomenon during operation. The fit gap between the two is very small, the rigidity is good, and the verticality of the sawing section is good.

3. Main transmission part

The main drive of this machine tool adopts variable frequency stepless speed regulation and high-performance reducer drive. The bearings are made of domestic Ha, Wa, and Luo bearings. The saw belt speed is 15-80min, and the saw belt twists vertically to cut the workpiece. The guide angle can be adjusted.

4. Saw frame, hydraulic cylinder lifting part

The saw frame adopts a steel plate welded structure, with the right pulley as the main driving wheel and the left pulley as the driven wheel equipped with a hydraulic tensioning device. The middle is equipped with a saw belt guide arm and a guide moving device. The saw belt iron filings are removed by a steel wire wheel, and the lifting is driven by a double hydraulic cylinder of large and small columns.

5. Guidance and moving device of saw belt

The saw belt is twisted by a guide device, and two sets of hard alloy guide blocks are installed inside the guide seat. The front and rear are equipped with bearing guide devices for fine adjustment.

6. Electrical box and electrical control box section

The electrical cabinet is a vertical cabinet type, placed on the left side of the sawing machine. The electrical components of the electrical box are centrally configured and installed inside. The frequency converter, transformer, and electrical components are separated, achieving stability and reliability of the electrical components, extending their service life, and greatly reducing the rate of electrical failures.

The electrical control buttons are located on the upper part of the control panel electrical box, and the entire machine tool can be operated through button control on the control panel. The entire electrical system is configured as follows: the frequency converter is selected from well-known domestic products, and the motor is selected from domestic Y series standard products.

7. Hydraulic pump station device part

Independent hydraulic pump station, hydraulic components adopt well-known domestic brands, oil tank capacity is about 60L or more, and the main pump of the hydraulic station is a variable pump. The unique hydraulic system adjusts the cutting speed through a speed control valve, which can prevent abnormal damage to the saw belt and achieve the best cutting effect.

8. Cooling device

The cooling device is installed on the side of the bed, and the water chamber is dispersed to various parts of the cooling device required by the water pump on the bed of the main engine. The trolley is designed with a coolant reflux device to ensure a reasonable overall design.

English

English chinese

chinese