Fiber Laser Pipe Cutting Machine

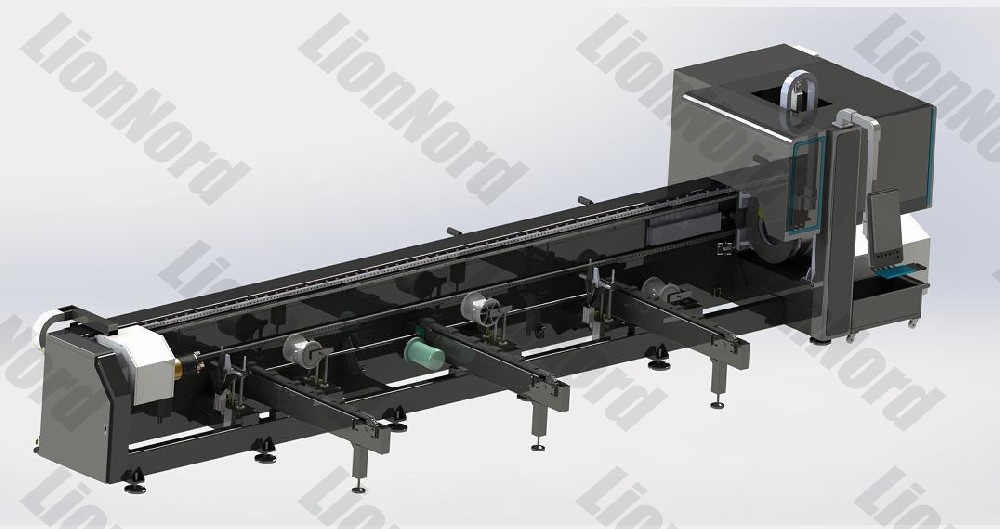

High Speed Multifunctional 3D Fiber Laser cutting machine with Unique semi-automatic slide loader

High Speed Multifunctional Fiber Laser cutting machine with Unique semi-automatic slide loader

Model LAN-220NC

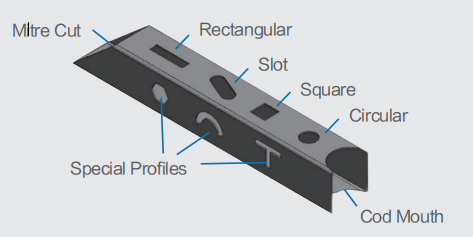

Tube material carbon steel, alloyed and stainless steel, brass, copper, aluminum alloy, etc. Tube shape round, square, rectangular, oval, L shape, U shape, etc.

Round pipe: 20 - 219mm

Square pipe:20mm ×20mm - 200mm ×200mm

Rectangular & other shaped pipe: 20mm -219mm

Benefits at a glance

Model | LAN-220NC |

Laser power | 3000W |

Tube material | carbon steel, alloyed and stainless steel, brass, copper, aluminum alloy, etc. |

Tube shape | round, square, rectangular, oval, L shape, U shape, etc.

|

Tube size | Round pipe: Ф20 - 219mm Square pipe:20mm ×20mm - 200mm ×200mm Rectangular & other shaped pipe: 20mm ≤ Diagonal ≤ 219mm |

Max Acceleration | 1G |

Single Tube Weight | 190KG |

Tube length | 5500-6500mm |

Pipe thickness | 0.6mm-5mm (depend on Material) |

Loading type | Semi-automatic slide loader |

X axis stroke | 7010mm |

Y axis stroke | 300mm |

Z axis stroke | 450mm |

W1/W2 axis stroke | 360° |

Machine dimension | 9400X2100X2200mm |

Machine weight | 5Tons |

Voltage | 380V 50or 60Hz 3phase (can add the voltage transformer to fit for local voltage ) |

1. Machine Features:

l High-strength and precision integrated machine bed

The machine bed is precisely made of open frame mechanical structure and welded with high-quality steel, which ensures it has excellent shock resistance, high rigidity and stability.

l Human–Machine Interaction design, convenient and simple operation

l High-precision 220 pneumatic chuck, faster and accurate cutting

Stable clamping with and acceleration of 1 G,rated speed 90r/min,When cutting tail material, the front chuck can move forward to avoid laser head and start cutting tail material, it can be controlled at about 50mm.

Special designed movable front chuck,Ultra short tail material

Unique movable structure of pneumatic front chuck. When cutting the last piece, the front chuck

can move a short distance to the right side, making the laser head able to cut the tailing in the back

chuck. The tailing could be controlled between 30-50mm while overall cutting accuracy is ensured.

l Max Photonics

The industry-leading Maxphotonics laser source has stable performance and long service life of key components 100,000 hours, the overall quality of the equipment is guaranteed. The laser can produce excellent beam quality, cut lines with higher precision, and higher working efficiency and better processing quality.

Photoelectric conversion efficiency is over 30%, it makes the cutting process more power-saving.

The working environment of the fully enclosed constant temperature laser is more effective to

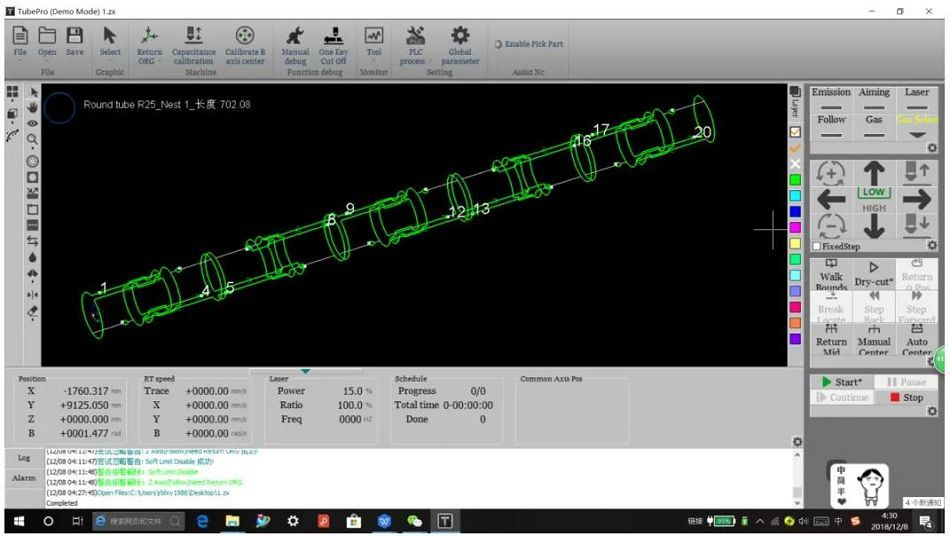

l Cypcut FSCUT control system

▶Professionally designed for professional tube cutting, supports production of tube and profile of various shape. It works with TubesT nesting software seamlessly to realize technique setting, advanced tool-path generation and nesting for standard and special production need.

▶Good compatibility for different drawing format include: NC code, DXF, PLT, AI, etc..

▶Fast and convenient automatic leveling and center correction function eliminates the cumbersome manual operation, improve the accuracy of cutting.

▶Automatically according to the size of the pipe to calculate the pipe rotation and single-sided cutting head when the lifting height, to avoid cutting the process of collision. But also greatly reduces the single-sided cutting when the unnecessary lift, save time.

l semi-automatic automatic slide loader

l Unique automatic slide loader

The LX-K9 is designed with a special machine bed structure, which is equipped with an automatic slide loader as standard configuration. Standard design is for maximum 6 pieces of tubes loading. Reloading time only take less than 10 seconds.

The suitable length of the loading is 5500mm-6500mm,

suit for the tube size : Round pipe: Ф20 - 219mm,

Square pipe:20mm ×20mm - 200mm ×200mm.

1. Laser Machine Operating cost

A. Power consumption

Item | Rated power (KW) | Total power (KW) | Total power consumption (Setting factor: 60%) | Hourly consumption (take 0.10USD /kWh as an example) |

Laser input power | 15 | 25.5 | 25.5 x 60% = 15.3 kWh / hour | 15.3x 0.10USD /kWh = 1.53USD / hour |

Machine bed motor power | 6 | |||

Chiller | 4.5 |

B. Cutting gas cost

Auxiliary gas | Requirements | Pipe Material | Cost | Hourly cost (USD) |

Air | Compressed air | SS/CS | 0.00 | 0.00 |

Liquid oxygen | Recommended purity 99.9% | CS | / | / |

Liquid nitrogen | Recommended purity 99.9% | SS | / | / |

C. Other consumables

Item | Hourly consumption | Remarks |

Protective lens | 0.05 USD | Each can be used for 3-5 months. |

Cutting nozzle | 0.05 USD | |

Total | 0.10 USD |

D. Total operating costs

No. | Air | Oxygen | Nitrogen | |

1 | Power consumption | 1.63USD / hour | ||

2 | Cutting gas cost | 0.00 | / | / |

3 | Other consumables | 0.10USD / hour | ||

Total | 14 USD / hour | / | / | |

English

English chinese

chinese