Fiber Laser Pipe Cutting Machine

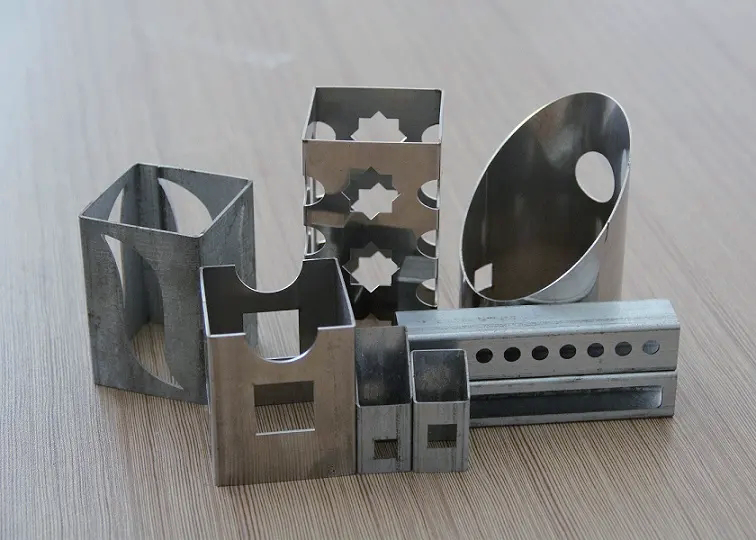

80MM metal pipe cutting machine by laser cutting for round and square

3D fiber laser pipe cutting machine suitable processing carbon steel, alloyed and stainless steel, brass, copper, aluminum alloy, etc.

Benefits at a glance

Model No. | LAN-80NC |

Max cutting size(diameter)

| 30-80mm |

Cutting pipe thickness

| 0.3-15mm(can customer as request) |

Max Cutting length

| 2000mm |

material feed way

| servo motor |

material clamp

| Hydraulic metal tube cutting machinery |

Laser power | 2000W |

Main motor power

| 4kw |

Machining accuracy | ±0.1mm |

Machine weight | 1000kg |

Machine size(L×H×W) | 2250*1300*1600mm |

Roller table size | 5800*1400*1200MM |

Our company's fiber laser cutting machines all use the industry-leading Chuangxin laser, which has stable performance and the service life of key components

Referring to the laser user manual, the overall quality of the equipment is guaranteed to be safe. Laser can produce excellent beam quality, finer cutting lines, higher work efficiency, and better processing quality. The fully enclosed constant temperature laser working environment effectively ensures the stable operation of the laser.

The equipment adopts Shenzhen Wanshunxing BT series cutting heads, which were launched by Swiss RAYTOOLS AG in 2019 and are suitable for use in China

A low-power fiber cutting head and diverse interface settings enable it to be paired with various mainstream fiber lasers. This cutting head adopts optimized optical design and smooth and efficient airflow design, which is extremely lightweight, compact, and easy to use. Combined with height sensors, it significantly improves cutting quality and efficiency. The laser head configuration varies depending on the power, and the following images are for reference only.

Servo motor: INOVANCE

Helps with servo performance for ultra high speed and ultra precision control. Maximize device performance and solve problems.

INOVANCE Electric's unique "adjustment free function" is further deepened. No need for tedious tuning tasks, stable movements.

◆ An energy-saving servo that can be used in harsh environments. Can smoothly build the best system on a global scale.

Meet safety standards and achieve visualization. Safe operating system

Water cooler:

◆ High quality stainless steel cold water circulation pump should be used, with large flow rate, high head, low noise, and long service life; Stainless steel water tanks, pipelines, and stainless steel valves will never worry about rusting;

The control system adopts a computer controller, with CPU fully automatic control, making the operation simple and intuitive. Control accuracy up to ± 0.1 ℃; Equipped with automatic fault diagnosis function, directly displaying the fault point on the screen, prompting users to quickly handle it to avoid damage to components and equipment;

The "dual temperature" precision water cooling machine not only provides stable and accurate water temperature control for the laser, but also provides a water temperature close to the ambient temperature for lens cooling, solving the problem of damage caused by condensation when using low-temperature water for cooling. It is the best choice for overall cooling of laser equipment.

English

English chinese

chinese