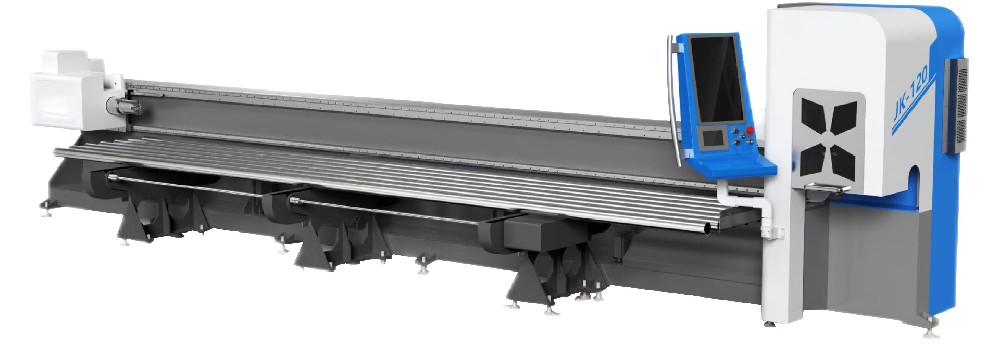

Fiber Laser Pipe Cutting Machine

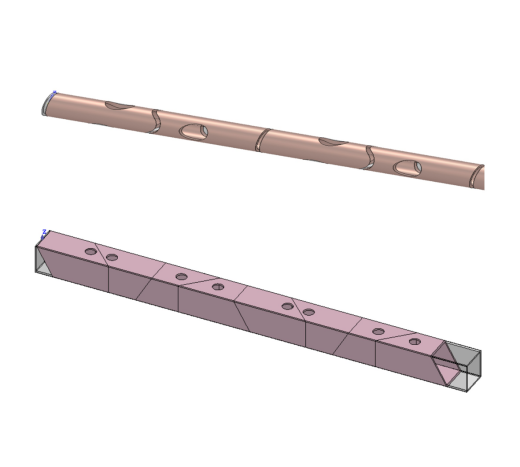

High Speed 3D fiber laser pipe cutting machine for metal pipe and tube with round and square

High Speed 3D fiber laser pipe cutting machine for metal pipe and tube with round and square

Max cutting size: Pipe 13-60 MM / square 15*15-60*60MM

Thickness :0.2-3mm

Max length:6000mm

Benefits at a glance

Name | High Speed 3D fiber laser pipe cutting machine |

Power of Laser | 1500 ~3000 W |

Model Number | LAN-90NC |

FLY-F9S is a trustworthy choice

• Why choose ?

• This is a simple and efficient laser cutting machine.

• Machine features

• 1. The mechanical structure adopts integrated bed design, with stable performance and stable equipment operation.

• 2. This model adopts fully automatic numerical control operation and human-machine dialogue interface.

• 3. The machine adopts totally enclosed protective device to prevent dust pollution, improve the service life of transmission parts and ensure the operation accuracy of the machine tool.

4. This model adopts AC servo motor drive system, machine tool motion adopts imported gear and rack drive, linear guide rail, to ensure the high-speed, stable, high precision, high reliability and long-term operation of the equipment.

Machine reference

3D FIBER LASER CUTTING MACHINE | |

Model No. | LAN-90NC |

Laser power | 2000W |

Tube material | carbon steel, alloyed and stainless steel, brass, copper, aluminum alloy, etc. |

Tube shape | round, square, rectangular, oval, L shape, U shape, etc. |

Max Acceleration | 1.5G |

cutting size(diameter)

| Pipe 13-60 MM / square 15*15-60*60MM |

Cutting Material

| SS/Steel |

Thickness | 0.2-3mm |

Raw material length | 6000-7000mm |

Max Cutting length

| 900mm |

material feed way

| servo motor |

X axis stroke | 7010mm |

Y axis stroke | 300mm |

Z axis stroke | 450mm |

Machining accuracy | ±0.1mm |

Machine weight | 1000kg |

Machine size(L×H×W) | 2250*1300*1600mm |

Roller table size | 7500*2000*2200MM |

weight | 2000kgs |

Description of main parts of the bed

The main frame of the bed: adopt the integrated welded bed structure, and then carry out rough machining (as shown in the figure below, large gantry machine tool), and then carry out vibration aging treatment. Natural failure can completely eliminate the stress of welding and processing, with good rigidity, high accuracy, and prevent deformation. Our company uses thickened plates to increase the rigidity of the bed, and the weight of the single machine is about 1.6 tons, so as to make the foundation more stable. As the saying goes, high-rise buildings are fundamentally based on the foundation. As the carrier of the whole parts of the machine tool, the bed directly affects the stability and processing accuracy of the machine tool for a long time.

Fiber laser

The latest generation of 1000W-6000W fiber laser is adopted for the fiber laser pipe cutting machine, which is easy to integrate, stable in performance and safe in overall product quality; The integrated overall structure of the fiber laser has no optical pollution, no coupling loss of power, compact structure, water cooling system cooling, and has high efficiency and reliability that other lasers do not have; It is applicable to a variety of material processing applications in various industries, especially in cutting and hole cutting applications in the pipe processing industry.

Standard Fiber laser

l High electro-optical conversion efficiency

l Strong anti-high reaction ability

l Efficient sheet cutting

l Output fiber length can be customized

l Maintenance-free operation

Main parameters of Fiber laser | |

Type | Fiber laser |

Work way | CW,QCW |

Transmission fiber diameter | ≥50μm |

Maximum tempering frequency | ≥50KHz |

Coolant way | water |

Output power stability | ±2% |

Energy output regulation | 10%-100% |

Central radiation wavelength | 1080nm |

Voltage | As requests |

Processing material | Stainless steel, carbon steel, aluminum, brass, copper, manganese, nickel and other metal materials |

Cutting head

Equipped with the special laser cutting head of Shanghai Jiaqiang laser cutting head and the non-contact automatic tracking system of the capacitor, it can automatically adjust the best focal length, ensure the best cutting effect of the whole plate, and avoid the material scrap caused by the change of focal length when the material is uneven.

Fiber laser cutting head

l The internal structure is fully sealed

l Cam focusing structure

l Drawer-type protective lens

l Auxiliary gas pressure:

l≤25bar

This cutting head has strong advantages in the application of medium and small power and small format fiber laser cutting. The internal structure of the laser head is completely sealed to prevent the optical part from being polluted by dust. Focusing adopts cam structure, which is accurate and convenient for adjustment. The protective lens is installed in a drawer type, which is convenient for replacement.

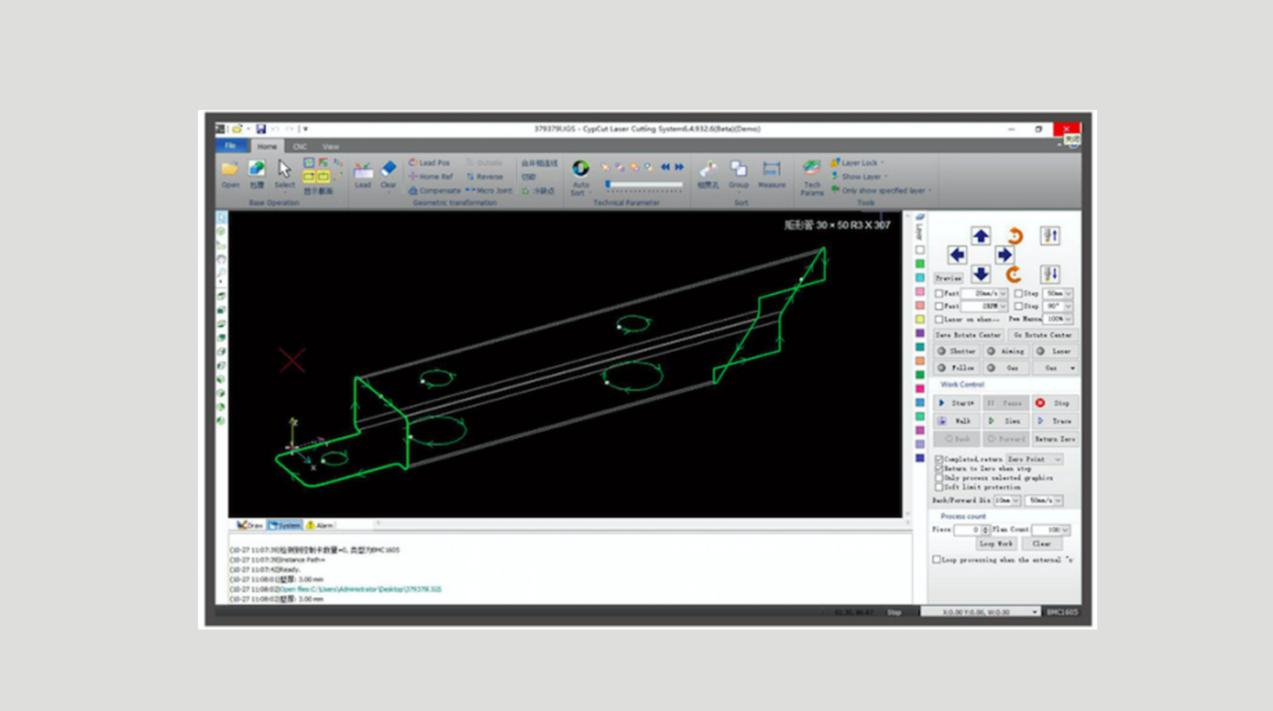

Machine system

This equipment adopts the FSCUT laser tube cutting control system based on PC control technology. Through CNC motion control software and related motion control hardware, it ensures high dynamic performance and can convert the potential energy of the laser generator into speed and efficiency to the maximum extent; With the pipe nesting software, the common edge cutting is realized, which saves more time and materials. Support and provide modularization, personalization, automation and informatization solutions.

System Software functions:

l Text and graphics processing function;

l Common edge cutting function;

l Automatic typesetting and automatic nesting function;

l Sharp corner processing function;

l Various cutting process processing functions;

Automatically generate reports;

Laser professional water cooler

The latest generation of Wuhan Hanli

Refrigeration is standard for machine tools

The dual-temperature and dual-control

high-performance water cooler has good cooling effect,

High reliability. The system adopts double

channels, double temperature and double

water control

Chiller system, one for cooling the laser, one for cooling the laser

Path is used to cool the external optical path, and the laser and laser

The head plays a role of cold and heat exchange during use,

Ensure cutting stability.

|  |

Reference | |

Power | 220v/50Hz |

Cooling medium | Distilled water/deionized water |

Water temperature control accuracy | ±0.1ºC |

Normal temperature water setting | standard 30 ºC(adjustable) |

Chilled water setting | standard 25 ºC(adjustable) |

High temperature alarm | 50ºC |

Low temperature alarm | -10ºC |

Processing capacity and scope

1: Typical cutting sample

Cutting speed table of various metal materials

1500W laser cutting reference speedometer

Thickness(mm) | Material | speed(m/min) | Auxiliary gas |

1 | Carbon steel | 6.5-9.5 | Oxygen/nitrogen |

2 | 4.5-6.0 | ||

3 | 3.0-3.8 | Oxygen | |

4 | 2.3-2.8 | ||

5 | 1.8-2.2 | ||

6 | 1.0-1.4 | ||

7 | 0.7-0.9 | ||

1 | SS | 6.5-9.5 | Oxygen/air |

2 | 4.5-6.0 | ||

3 | 2.8-4.0 | ||

4 | 2.1-2.9 | ||

1 | Aluminium alloy | 6.0-9.0 | Oxygen/air |

2 | 5.0-6.0 | ||

3 | 2.9-4.3 | ||

4 | 2.0-2.8 | ||

1 | Brass | 5.3-6.3 | Oxygen/air |

2 | 3.7-4.8 |

Operation cost analysis

Total electric energy consumption cost

Model | Power(KW) | Power Consumption (Power factor 60%) | Consumption /hour (The electricity charge is 1 CNY/KW) |

FLY-F9S | 15 | 9 | 9CNY/hour |

Main standard configuration

Name | QTY | Brand | |

1 | Fiber laser | 1 | Ruike/Chuangxin |

2 | fiber cutting head | 1 | shanghai |

3 | Mechanical platform and accessories | 1 | LJX |

4 | Precision linear guide | 3 | TBI |

5 | ball screw | 1 | TBI |

6 | 5grade gear rack | 2 | YYC(China Taiwan) |

7 | Rotating tube gear | 1 | (China Taiwan) |

8 | Reducer | 3 | Germany |

9 | control software | 1 | China |

10 | Full-automatic chuck | 1 | Taiwan |

11 | AC servo motor and driver | 5 | China |

12 | electric control | 1 | Schneider (France) |

13 | Air circuit control | 1 | YADEKE/SMC |

14 | Water cooling unit | 1 | HANLI |

Equipment related technical requirements

1. The processed pipe shall be free of serious corrosion, which will affect the quality of the cut section.

2. The distortion and bending of pipes shall not be lower than the Dimensions, Shape, Weight and Allowable Deviation of Cold-Formed Hollow Section Steel for Structure (GB/T 6728-2002).

3. Pay attention to the safety of people and equipment when loading pipes. When using the crane to load materials, it is required to be operated and transported by qualified professional personnel. The crane is required to have fast and slow functions. When the baler approaches the equipment, it is required to use the slow function to approach the loading platform.

4. The pipe material shall be flat and straight, with bending of 1mm/1m (4mm/6m).

5. The outer diameter tolerance of the profile shall not be greater than ± 0.5% of the outer diameter, and the minimum shall be 0.2mm (according to the standard outer diameter deviation grade D4 of GB/T 17395-1998).

6. The total twist in the length direction of the pipe shall be less than 0.02% of the total length.

7. Workpiece processing accuracy; Based on the material error, the position error is IT12 and the shape contour error is IT12.

8. The roughness of the cut 0-6mm section is 6.3um-12.5um, which varies with the thickness of the material.

9. The rear end of the pipe is irregular, and the maximum error is less than 100mm.

10. The end of the pipe is cut off by the flying saw and has thermal burr. The height of the burr should be less than 3mm.

Because the weld height affects the penetration and clamping action of the laser, when the pipe is processed as welded pipe, the external weld height shall be removed and basically flat, the external weld height shall be less than 0.3mm, and the internal cavity weld height shall be less than 2mm.

English

English chinese

chinese