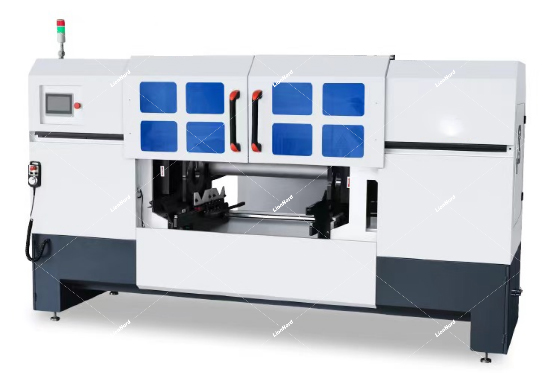

Tube End Forming Machine

cnc automatic big size pipe chamfering machine

Features of chamfering machine:

1. Manual/Auto material feeding, automatic clamping, automatic chamfering, and automatic discharge.

2. Reverse three faces (flat, inner, outer) at once, and complete both ends simultaneously.

3. Servo motor drives ball screw feed, with high precision

4. The human-machine touch screen is easy to operate.

5. Using the Huichuan controller, the computer control has high stability, and the electronic control components adopt CE certified products.

6. The automatic feeding device adopts linear guide rail and gear rack transmission, and the clamping adopts cam transmission to ensure synchronous action.

7. The computer will automatically record the processing quantity.

8. The fixture design is simple and convenient for disassembly and assembly.

9. The chamfering spindle adopts a retractable spindle for feed (capable of heavy cutting)

10. The cutterhead can hold three knives, with adjustable cutterhead angle and adjustable pipe diameter

Benefits at a glance

Machine model | 160NC |

Machine control | CNC PlC |

Saw head Move | Automatic |

Length position | Automatic (set in PLC ) |

Chamfer tools | CNC carbide knife |

Processing capacity | 50mm-160mm |

thickness | 1mm-6mm |

length | 45mm-900mm |

Accuracy | ±0.1mm |

Processing speed | 7-10s/pcs |

voltage | As requests |

Machine | 2800*1500*1200mm |

Machine weight | 2200kg |

Auto loading machine | Dia 50-160mm, length <200mm |

1. Technical parameters of NC50A-160 double head chamfering machine

2. Diameter range 50-160mm;

3. Length range 50-1000mm;

4. Wall thickness of 2-7mm;

5. Processing requirements: inner and outer chamfers+flat end faces, without burrs;

6. Press the aluminum tube at both ends with a clamping fixture (because the raw material has an ellipse);

7. To quickly change the type and replace the clamping fixture; The contact surface between the fixture and the steel pipe is clamped with rubber to avoid surface damage to the steel pipe.

8. The length adjustment adopts ball screw, and the servo adopts absolute value encoder; D

9. Each size has a cutterhead, and only the cutterhead and clamping fixture are replaced during the mold change. The program can be switched with one click (the nose end of the spindle is a standard chuck spindle, which can also be tapered);

10. The spindle is controlled by a frequency converter;

11. Automatic feeding rack that can move with the main axes on both sides (convenient for changing types);

12. Consider mechanical sub materials at the cutting point (consider adding mechanical sub materials in the future);

13. The equipment is equipped with a protective cover, and the door adopts a pneumatic telescopic door for easy operation

14. Aluminum shavings are easy to clean, and aluminum shavings collection box;

15. PLC has network access. Can achieve later network connection

Features of chamfering machine:

1. Manual material feeding, automatic clamping, automatic chamfering, and automatic discharge.

2. Reverse three faces (flat, inner, outer) at once, and complete both ends simultaneously.

3. Servo motor drives ball screw feed, with high precision

4. The human-machine touch screen is easy to operate.

5. Using the Huichuan controller, the computer control has high stability, and the electronic control components adopt CE certified products.

6. The automatic feeding device adopts linear guide rail and gear rack transmission, and the clamping adopts cam transmission to ensure synchronous action.

7. The computer will automatically record the processing quantity.

8. The fixture design is simple and convenient for disassembly and assembly.

9. The chamfering spindle adopts a retractable spindle for feed (capable of heavy cutting)

10. The cutterhead can hold three knives, with adjustable cutterhead angle and adjustable pipe diameter

English

English chinese

chinese